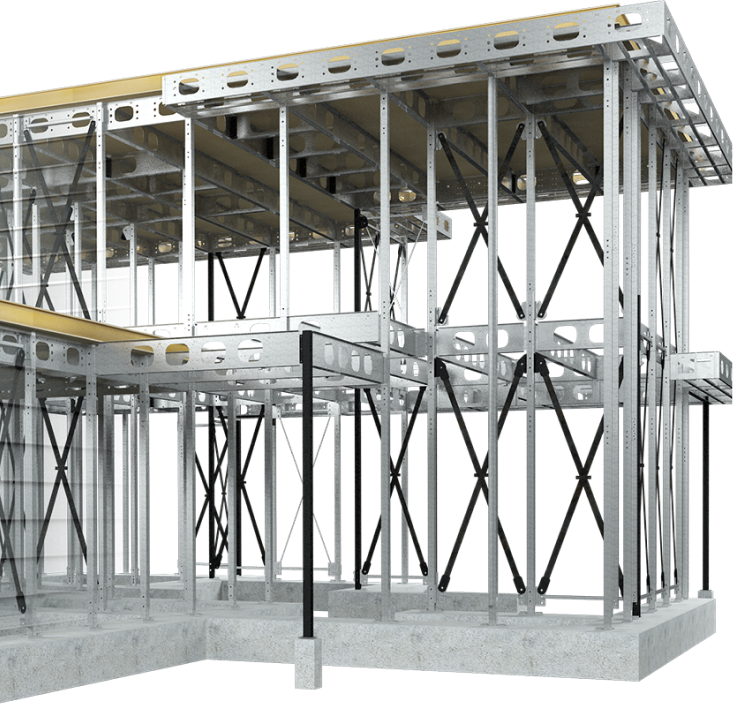

Light Gauge Steel Structure

Strong, Lightweight, and Built to Last!

Coolmax Light Gauge Steel Structures provide strong, lightweight, and energy-efficient building solutions for residential, commercial, and industrial applications.

INTRODUCTION

INTRODUCTION

Light Gauge Steel Structure

Founded in 2015 COOLMAX has become a reputable name in the field of Light Gauge Steel Structures. Durability and long-term consistent performance – that’s what you get with steel. Reduced structural capacity due to dry-rot, termites, or mold will not compromise a steel structure in an earthquake.

Buildmax building system

Buildmax building system

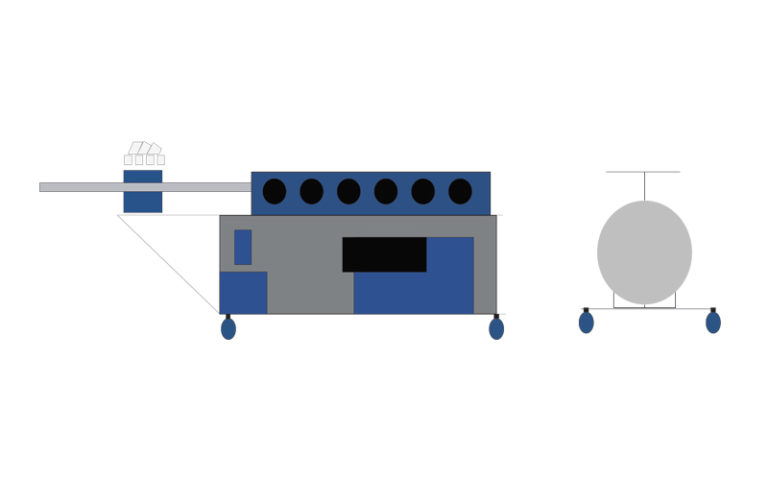

PRODUCTION FACILITY

Our production facilities include a dedicated CNC based fully automatic Light Gauge Steel roll former controlled by our latest CNC software capable of Producing track, studs with automatic operations from cutting to notching from an automated decoiler.

WHY TO CHOOSE?

WHY TO CHOOSE?

KEY BENEFITS

-

Super fast

-

Light construction

-

Sustainable

-

Incredibly strong

-

Resistant to weather

-

100% in accordance with requirements

-

Clean construction site

-

Off-site design & production

-

Limited transportation requirements

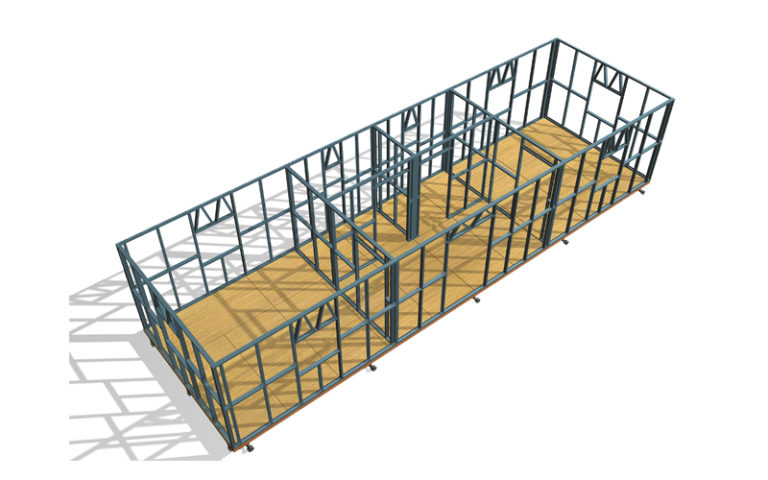

Building Process

Building Process

See how we work

Step 1

The process begins with clients plans including building size, total rooms, toilets & other allied services required. Based on plans the Light Gauge Steel buildings are designed which include load bearing walls, non-load bearing walls, trusses & roof panels which are further translated into CNC based machine codes to be translated for FABCAD roll former via our especially designed software.

Step 2

Roll forming the designed buildings is then processed for elementary wall section production in the shape of C channel roll forming via a dedicated computer which operates on FABCAD software (CNC based LGSF rollformer program), the production is completely automated and computer controlled which is capable of producing 100 sq.ft per hour.

Step 3

Wall markings and stacking as the wall sections are produced are marked in accordance with the drawings which are used for referencing in the erection process. The walls are then stacked and packed to be delivered to sites for further building.

Step 4

The Structural erection of the Light Gauge Steel building structure is then erected and anchored on the floor which can be either a dedicated building foundation, rooftop building extension, or steel based skids (PORTACABINS).

Step 5

Building insulation and cladding on the erected structure is then insulated using fireproof mineral wool insulation to keep the building thermally insulated, the structure is then cladded with fireproof and weatherproof composite Fiber Cement and the building inside is placed with composite plasterboard.

Step 6

The Roofing of the completed structure is then roofed via either trusses or roof panels at specified spacing in order to withstand a windfall of 100 miles/hr. The final step towards building completion includes interior and exterior paint jobs, placement of windows, doors and finalizing the electrical and plumbing works.

Our Brands

Our Brands